What are Gerber files and how they are used in PCB manufacturing process

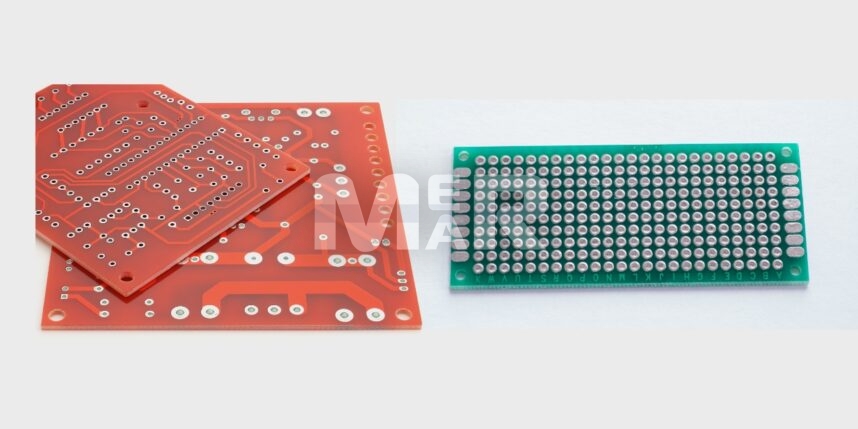

For your electronics contract manufacturer to create PCBs meeting your bespoke requirements, what is essential is the manufacturing documentation to be robust. An extremely important document is the PCB Gerber file that is used to create the circuit board.

Let us look at what PCB Gerber files are, in some detail.

What are Gerber files?

The PCB Gerber files were initially developed by a company called Gerber Scientific, founded by Joseph Gerber, and have become the benchmark for consistent production of printed circuit boards.

A PCB Gerber file is developed to detail the printed circuit board requirements in every stage of the product development. These files are used for both PCB fabrication as well as PCB assembly.

Gerber Files are open ASCII vector format files. What they contain is information on every layer of the PCB. All objects on the circuit board such as vias, solder mask, silkscreen images and more, all find representation by way of vector coordinates. It is these files that are then translated into the PCB.

Gerber File Extension

As for the generation of Gerber files, they are generated as per the RS-274X Gerber format. Gerber files typically come with the following extensions:

- .gb

- .gbr

How are PCB Gerber Files Generated?

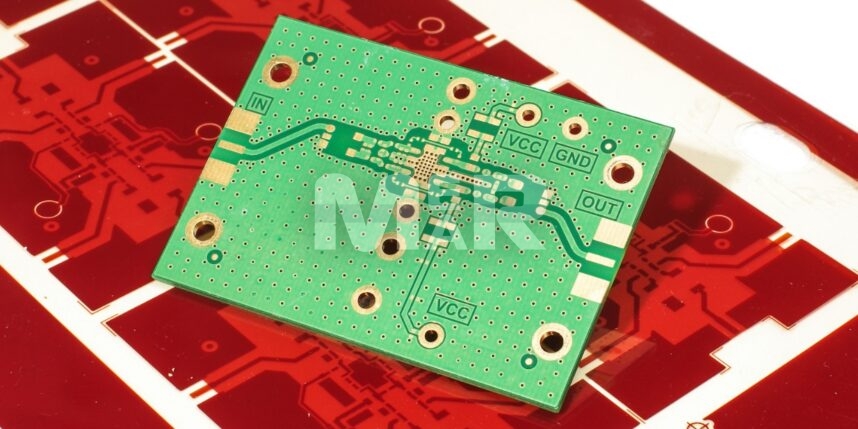

Once the design is complete, you need to create the PCB Gerber Files for the manufacturer. While earlier this used to be a cumbersome process with many steps involved, today the CAD packages have simplified the process. What you need to do is to produce an individual file for each layer of the board. Additionally, there would be separate files for the solder mask layer, top and bottom silkscreen layers, and top and bottom solder paste layers. Some manufacturers will also require Gerber layers for PCB assembly information, particularly if your design configurations are unique.

The files are typically zipped into a single file. The file names are descriptive enough so that the contract manufacturer can understand which board layer the file has to do with. Supplying a stackup marked as the silkscreen layers, Gerber files are labeled within the zip file works well to avoid any errors.

An important aspect to remember before you create the PCB Gerber files is to configure the Gerber file generator. This will ensure that the formats and units are consistent. Another file that is created along with the Gerber File is the NC Drill file. This is a documentation that instructs where the holes are to be drilled in the board.

PCB Gerber Formats

1. RS274-D

This is the oldest format where the file is represented in numerical control format. This was compatible with the photo plotters used in the 1970s. However, on account of several disadvantages of the format, manual input of d-codes and more, the use of these files is fairly restricted and several other Gerber files have been developed.

2. RS274X

This format has been in use since 1998. This uses an embedded format, unit, and data information. This allows for standard sizes and custom apertures. The other advantages of this format include:

- Multiple layer structures for single layers

- Polygon Fill Commands

- Polarity Controls

- Elimination of manual data entry

- Reduction of photo plotting errors, and more.

3. ODB++

This is a highly standardized input format and automates the process for stack up, drill placement and labeling. It is now widely used by most CAD programs. The added advantage with this is that there isn’t room for any manual errors as the need for manual naming conventions was taken away.

4. Gerber X2

This is the latest format used by advanced CAM software applications. Some of the attributes that this allows to be applied within the Gerber file include:

- Function of file

- Part represented by the file

- Function of pad

Documentation after PCB Gerber Files

It is important to ensure that all your files are well documented. What you need is to have the following in place:

- Fabrication & Assembly drawings

- Pick & Place data

- Test Data

- Schematic Netlist

- Readme File

Last, but definitely not least, it is important to work closely with your contract manufacturer to ensure that you provide the necessary details for the best results.

Mer-Mar Electronics is an ISO 9001:2015 certified company and ITAR (International Traffic in Arms Regulations) compliant manufacturer that delivers one-stop PCB manufacturing services with specialized support, reliable testing, and multi-functional features. Our consistent quality and quick turnaround time captivate our customers, who look to us as a one-stop shop for all their PCB requirements. To know more contact us at sales@mermarinc.com or call us on (760) 244-6149.