How to prevent PCB tombstone and open defects during SMT process?

Tombstone is a common defect that occurs when SMT components are lifted from the PCB pad. The lift may be partial or complete. While one end is soldered, the other stands up. Visually this gives the appearance of a tombstone in a cemetery, hence its name. Tombstone defect is also sometimes known as the Manhattan effect, Drawbridge effect, or Stonehenge effect. Tombstoning isn’t just limited to passive devices. It can also occur on surface mount devices and can prove to be a fatal defect;

YOU MAY ALSO LIKE: In-circuit Testing

SMT tombstone root causes

In fact, incidents of tombstoning are on the increase on account of two major issues:

- Increasing miniaturization

- The transition to lead free

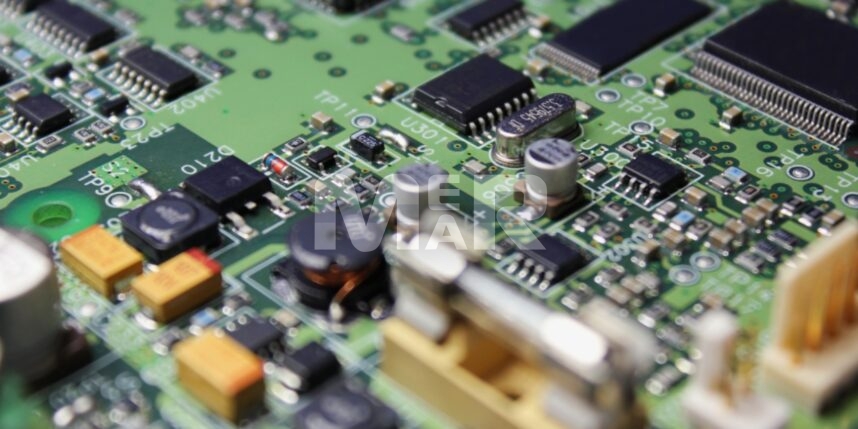

Essentially the tombstone defect is caused on account of the fact that different wetting speeds result in imbalanced torque. Wetting refers to the solder reaching a fluid state so that it can attach to a component lead or pad. In an ideal situation, the solder attaches to both pads and the wetting process is uniform at both ends. It is unbalanced soldering, however, that causes the issue of tombstoning. However, tombstones can also result on account of a number of other causes during SMT Process, such as:

- Improperly designed solder pads

- Different sizes of the pads

- Inaccurate placement of components

- Uneven reflow oven temperature

- Presence of nitrogen

- Chip is placed parallel to the reflow oven

PCB rules to prevent tombstoning

To ensure that PCB tombstoning does not occur, you need to take care of the following during SMT Process:

1. Pad Dimensions

It is important to ensure that the pad dimensions are correct. Making them too large, too small or having one pad of a different size can all lead to tombstone defect as one side of the pad could complete wetting before the other.

YOU MAY ALSO LIKE: Prevent Cause of Device Failure Using High-Speed PCB

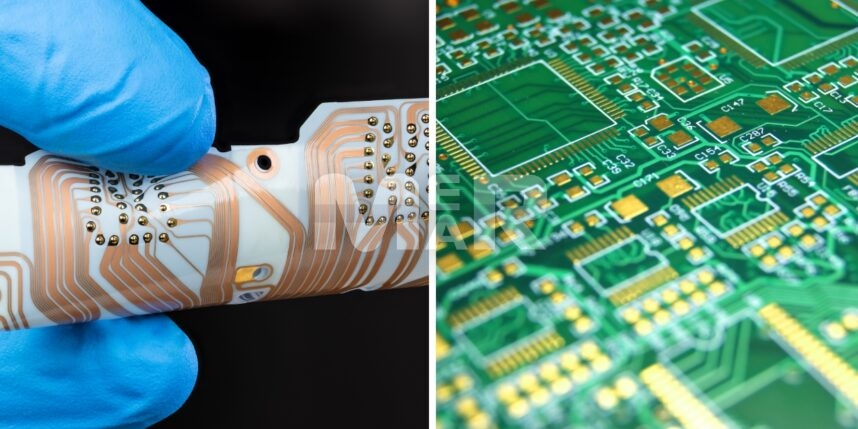

2. PCB Finish

With small component sizes such as 0402 or 0201 it is advisable to use a different PCB finish as opposed to the traditional Hot Air Solder Leveling. Although HASL is known for its low cost, the fact is that it can also cause uneven surfaces, which in turn leads to the tombstone defect.

YOU MAY ALSO LIKE: Prevent PCB Bending

3. Component Placement

Component placement and routing play a major role when it comes to tombstoning, especially when the components are small. It is imperative to check that the traces connecting the pads are equal in width. You also need to ensure that the traces are connected in a similar orientation.

4. Copper Coverage in the Inner Layer

If the inner layer of the board has unequal copper coverage, it can lead to uneven heating process, which in turn can lead to the tombstone defect.

5. Solder Mask Thickness

Although the solder mask plays a big role in guarding against oxidation, it can also restrict the solder movement. It is therefore important to carefully evaluate the solder mask thickness

6. Stencil Design

This in turn has two aspects- aperture design as well as stencil technology. A good stencil design ensures that there is adequate solder paste. If the solder paste is too much it results in greater torque. Also there needs to be appropriate component to paste overlap. If the overlap is too little there will not be adequate adhesion. On the other hand, if the overlap is too much solder beads will show up on the side of components.

The good news is that tombstoning is preventable. Attention to its causes can ensure that incidences of tombstoning are reduced and that there is reduced need for reworking.

Open circuit defects in PCB

Another commonly occurring defect is what is known as the Open Circuit defect. This is known to occur when there is an electrical continuity between at least one terminal of the chip and the solder pad. Open Circuit Defect is caused by many of the same reasons that cause tombstone defect. However, there are some additional factors as below:

- There is oxidization in components

- Inaccurate pad sizes

- Poor flux

In order to correct open circuit defect, the following actions are required:

- The pad sizes need to be kept to the specifications

- Gradual soak ramp rate needs to be adhered to

- The pressure for pick and place nozzles needs to be adjusted

Mer-Mar Electronics has 4 decades of experience in providing high-quality SMT PCB assembly in the USA. We provide all-in-one SMT PCB Assembly Services for leading edge and accurate components mounting. Whether you require SMT PCB assembly, SMT SMD PCB, Surface Mount assembly or any custom SMT PCBs; You can get a quick PCB assembly quote based on your custom requirements.