Conformal Coating – Protect PCBs from adverse environment conditions

The conformal coating has a very important role to play when it comes to protecting circuit boards against unfavorable environmental conditions. In environments that have extremes of temperature, moisture, and dust, circuit boards can often suffer from defects, compromising the shelf life of the product. The conformal coating acts like a protective film that keeps the PCB moisture-f, and dust-proof protects it against temperature variances, keeps it free from corrosion & more. Another common aspect that impacts printed Circuit Boards wide variety of pollutants. They can lead to corrosion and even failure of PCBs. While several pollutants could accrue from the operating environment, oftentimes there are a lot of contaminants on account of residues during the PCB manufacturing process.

Uses of Conformal Coating in different sectors

The application fields of conformal coating include, but are not limited to:

1. Consumer Electronics

Consumer electronics particularly must face harsh external conditions. Be it water and detergent in the case of washing machines and dishwashers or contaminants as in the case of computers, microwaves and others.

2. Automobiles

With break fluids, gasoline vaporization & more, there are enough and more reasons for the use of conformal coatings in automotive.

3. Aerospace

With compression and decompression being the norm, it only stands to reason that the aerospace industry should see a widespread application of conformal coating.

Components that shouldn’t have conformal coating

It is also important to remember that some components cannot receive conformal coating. Some such components include:

- High power components

- Adjustable resistor

- Battery holders

- DIP Switch and more

YOU MAY ALSO LIKE: PCB CONFORMAL COATING VS PCB POTTING

Benefits of Conformal Coating for PCB Protection

While the benefits of using conformal coating are well established, however, to reap the benefit of conformal coating, it is imperative that some preparations be made in the design phase itself.

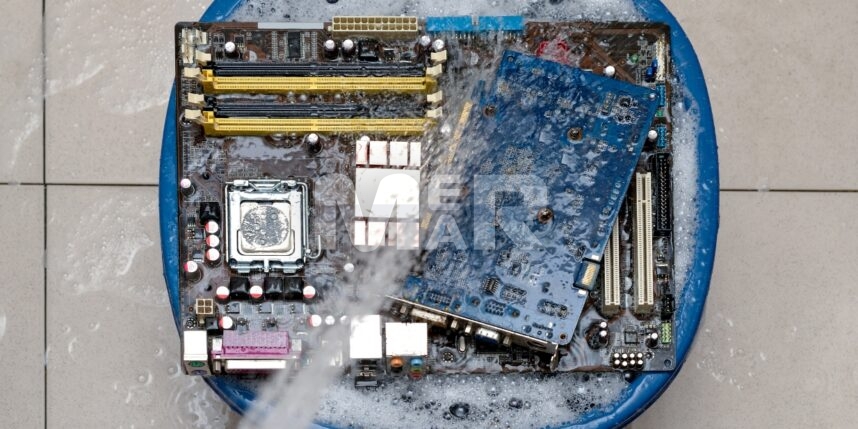

You need to make sure that there are no contaminants on the board as contaminants can be sealed in and can create issues in the long run. In fact, the boards need to be thoroughly cleaned as well as dried. This will go a long way in ensuring that long-term performance isn’t impacted.

Conformal coating is also not effective in the case of applications that are exposed to water significantly. In such cases, it is advisable to offer protection through the process of encapsulation.

Ideally PCB conformal coating works best for applications which have:

- Good electrical properties

- Chemical resistance

- Are durable mechanically

Also, the conformal coating does not work well over sharp edges as it results in edge crawling where the coating isn’t present on such edges. To prevent edge crawling it is necessary to check the viscosity of the coating and use multiple coats. A specialized coating of 100 microns works best for improved edge cover.

Some of the tests that might be carried out on conformal coated boards include:

- Damp heat testing

- Thermal cyclic performance

- Chemical resistance test

- Flammability test

Conformal coating is normally applied by the process of dipping or spraying. Typically, the thickness of the coating is 20-50 micron, even though specialist coatings can be applied at up to 100-micron thickness. In the case of PCB Prototypes or small batch production, it is also possible to apply the coating by the process of brushing.