How to Choose the Right PCB Assembly Company in California?

PCB Assembly is an extremely crucial phase in the printed circuit board project. It is thus important that you choose the right partner who can do justice to your project. In choosing the right PCB Assembly Company in California, there are certain key factors that you must keep in mind so that the bespoke needs of your project are met. Especially if you are a company, which requires small batches or prototypes to be manufactured, you need to choose a company that accepts minimum quantity requirements and sticks to timelines, so there is no cascading effect of delays. While we look at costs as the primary determining factor, the fact is that a host of best practices need to be watched out for as well. Here are some of them aspects to consider:

Cost

Cost is a most important aspect to hire California PCB Assembly Company. However cost alone cannot be a determinant to choose the supplier, as quality will play a far bigger role. Poor quality and hence redoing the prototype can prove to be extremely costly especially in terms of loss of time that can prove to be fatal in a scenario where time-to-market is of essence.

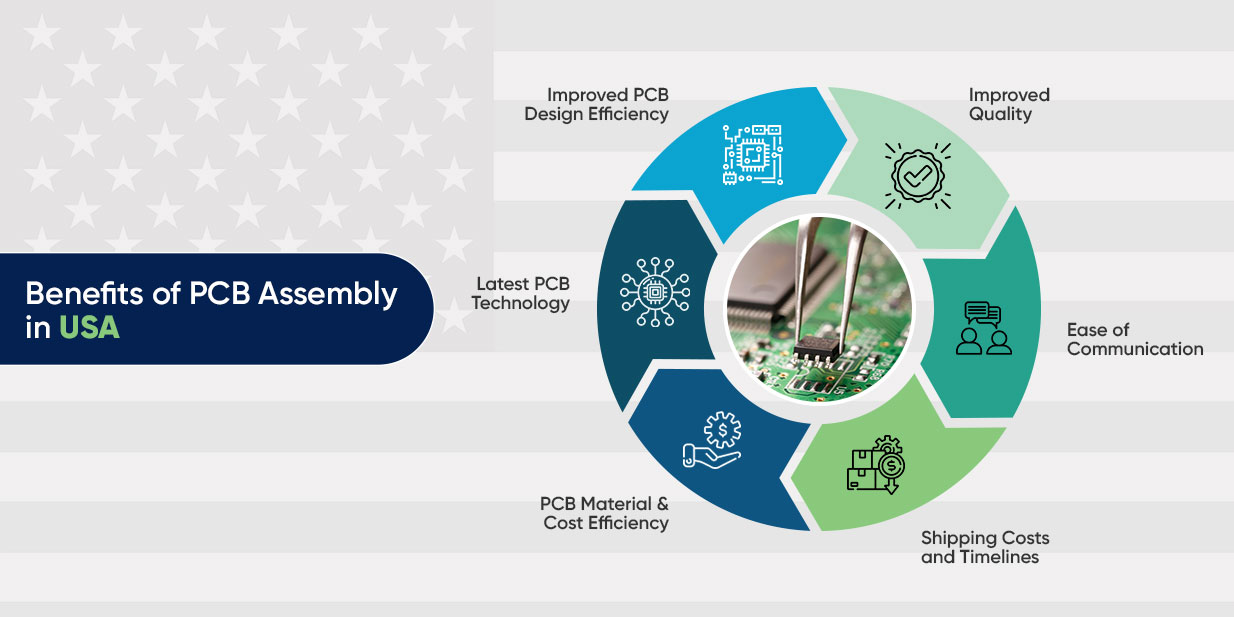

Technology

It goes without saying that the PCB Assembly company that you choose, has to have state-of-the-art technology to do justice to the product. BGA Assembly and rework capability, sophisticated pick and place equipment, testing services for the boards etc are something of the things to watch out for.

Turnaround Time

Again this factor is extremely crucial as quick turnaround times can help you in turn to improve the time-to–market. Any delay in turnaround time, on the other hand can lead to cascading delays, which can throw you completely out of gear.

Customization

When it comes to prototypes, what you need is a bespoke product suited to your specific needs. You need to therefore ensure that you go with a supplier who has enough experience and facilities to offer what you envision. Also the supplier’s rich experience should be able to guide you to make any changes in design that will impact manufacturability.

Industry Experience

Ideally you should look at a PCB Assembly company that has robust experience in your domain. This will enable you to benefit from their experience as they will be able to offer rich inputs

Security

In a competitive market, it is essential that the PCB Assembly Company offers adequate protection when it comes to your intellectual property rights and classified information.

Safe Packing & Shipping

Look for a PCB Assembly provider that follows safe packaging & shipping, so that you are sure that the product isn’t damaged during shipping.

Other than these aspects, you need to look for a host of best practices that a PCB Assembly Company should follow:

Quick Quotations

In a competitive market where time is of utmost essence you should not have to waste precious time waiting for quotations. Quick quotations are also useful since you may want to know the pricing at different levels of quantity that you may require. This will in turn help you arrive at the product costing on a proactive basis. Go for a provider who is quick with turnaround times when it comes to quotations.

Prototypes

If you are a start up or are adding a new product to an existing product line, what is of tremendous importance is that a robust prototype be made available to you at a reasonable cost. PCB Assembly Companies can make this possible by combining low volume orders into a large production run and therefore still offer economy of scale. This is also made possible through the use of latest technology.

On shore manufacturing

Another area to look for is on shore manufacturing, as that can take away delays on account of shipping. You could also avoid the many complexities that could arise with an offshore manufacturer, also Choose the best PCB assembly manufacture.

Value Added Services

Beyond just PCB Assembly, a professional company can offer a host of other services including but not limited to warehousing and sometimes even sending the final product directly to the end consumer.

A quick scan of the above aspects will ensure that you team up with the right PCB Assembly Company that will bring value to the table and provide you a distinctive edge.