Top PCB layout tips and tricks to relieve the swelling of post-assembly rework

Once the PCB components are placed on the board and routed, any requirement that calls for a sizeable amount of rework, can prove to be extremely cumbersome. Not only does it take time that in turn impacts go-to-market and impacts your competitive advantage, it also comes at a cost. Additionally, if your board hasn’t been designed to support rework, it makes the job even more difficult. In such cases, rework can also impact other sensitive parts in the vicinity and lead to further complications.

Fortunately, there are some handy PCB layout tips and tricks, which if followed, can go a long way in reducing the amount of rework required.

Before we look at these tips, it will be worthwhile to examine what are some of the PCB rework issues that are typically encountered:

Typical PCB Rework Issues

Part Replacement – Sometimes a wrong part may have been initially specified. A seemingly small lapse, it leads to wasted time, effort and costs.

Defects in Assembly – A big part of the rework is required when parts haven’t been soldered correctly during assembly. Sometimes these PCB soldering issues can be on account of improper DFM clearances or incorrect component locations.

Inaccessible Parts – Sometimes it is hard to replace parts or rework them, on account of the fact that the parts are either too close to other parts or sometimes even hidden. If the part is positioned in a manner that tools cannot reach them, it can be a big issue that can impact rework.

Damage – Parts that are placed very close to the components that need rework can also be damaged. The damage can happen on account of heat of soldering reaching these parts or any physical damage while replacing other parts. The rework process therefore may lead to reworking on these collateral damages too.

Needless to mention that rework also becomes a deterrent when you are chasing a deadline and also trying to keep things under budget.

PCB layout Tips to reduce post assembly rework

Here are top handy layout tips that when implemented well can go a long way in avoiding or minimizing rework issues:

-

Accurate BOM – Now this is a gold standard when it comes to avoiding rework. Sometimes the part information in the design isn’t updated or the schematic isn’t synchronized with the layout. In turn, it leads to reworking incorrect parts. It is imperative, therefore, that the BOM is totally in sync with the PCB design and layout.

-

DFM guidelines – A lot of the rework related to parts being placed in the wrong location or parts not soldered correctly can be avoided if the DFM guidelines are clearly specified and are followed accurately.

-

Room for rework – High density of parts is a function of miniaturization of devices. The components also need to be placed tightly together to ensure signal integrity. However given these constraints it is important to allow some room for rework. The PCB contract manufacturer will be in the best position to offer recommendations to be able to incorporate room for rework within the constraints.

The need to choose the right PCB contract manufacturer

As the complexity of a printed circuit board increases, so does the potential for rework. The right contract manufacturer given his expertise and access to industry best practices will be able to minimize the potential of rework. That said, even with all the precautions there will be some PCB assembly defects that can occur which an experienced PCB manufacturer will be able to cater to.

While potential rework situations need to be taken into account, what also need to be planned for are aspects such as:

- Some printed circuit boards need additional testing.

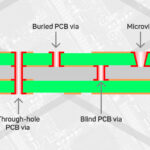

- Sensitive components need room for access. This may include additional vias for probing or header pins for test access.

An experienced and skilled PCB contract manufacturer can easily identify areas of the board that may need more room for rework or for extensive testing. Besides, a skilled PCB contract manufacturer will also have the engineering prowess that will be of utmost importance when it comes to meticulous rework in the least amount of time and with minimal added costs.

At Mermar Electronics, we have 4 decades of solid experience in assembling printed circuit boards, PCB design and PCB assembly rework and repair service through innovative tools and technologies. If you have any requirements or inquiries related to PCB manufacturing, Get a quick quote, or simply drop an inquiry at sales@mermarinc.com