What are the Most Significant Advantages of Multilayer PCB?

The demand for multilayer printed circuit boards is ever increasing, led largely by the need for compact, miniature, and lightweight appliances that offer sophisticated functionality.

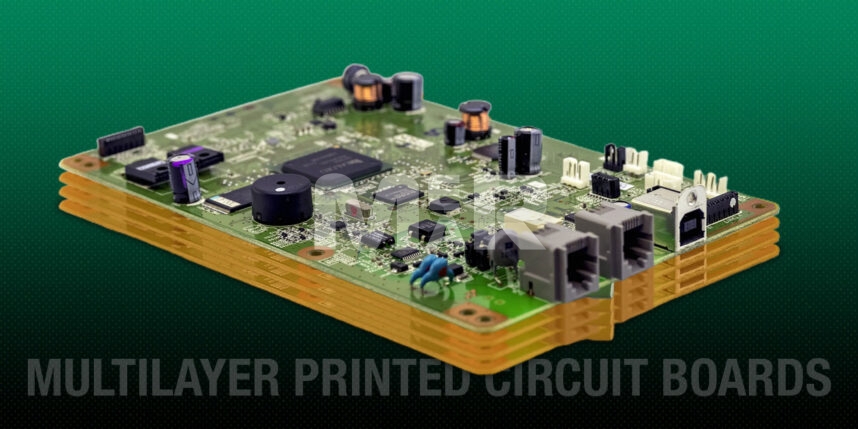

Before we look at the many advantages of multilayer PCBs, it will be worthwhile to understand what a multilayer PCB really is.

What is a Multilayer Circuit Board?

As its name suggests, as opposed to a single layer board, a multilayer board contains three or more layers of conductive material. Other layers, often comprising of often copper foil, stack on this core. They are clearly more complex than, single-sided or double-sided PCBs. A single layer printed circuit board has a single layer of conductive material while a double-sided one functions with more layers than a single layer board but fewer than a multilayer PCB.

Advantages of Multilayer PCB

The significant multilayer PCB benefits include:

1. High Quality

A significant increase in functionality with the incorporation of multiple layers. Multilayer boards result in high-quality, reliable products.

2. Increase Space for Additional Component

With the extra layers what opens up is added real estate. Signal and power traces can be shifted to the internal layers where there is space for direct connections. What it also does is frees space on the board’s external layers for additional components.

3. Improves Electrical Performance

On account of their innate electrical properties, they offer high capacity and speed. They also solve electrical performance issues such as:

A. EMI Shielding

It is possible to configure the layer structure so that multiple ground planes are included. In turn, these ground planes act as a shield against electromagnetic interference.

B. Signal integrity

It is possible to configure multilayered boards with microstrip and to sandwich high-speed transmission lines. In turn, these ensure better signal paths as also reduce noise.

C. Power integrity

With full metal power and ground planes power is distributed well. Besides, the planes also absorb any power spikes.

D. Thermal control

Multilayered boards ensure heat dissipation throughout the board layer stackup.

4. Reduce Overall Weight & Connectors

They significantly reduce the need for multiple connectors. Not only does this result in simplifying construction, but importantly, it also results in reducing its weight.

5. Other Advantages of Multilayer PCB

- Multilayer PCBs also lend themselves to both rigid and flexible boards.

- The high density also results in increased durability.

- The boards lend themselves to stringent testing processes resulting in a high-quality product.

YOU MAY ALSO LIKE: Types of Multilayer Flex PCB

Challenges Associated with Multilayer PCB

This is not to say that multilayer PCBs do not come with their own set of challenges, the primary among them being:

- Since specialized processes are involved in the manufacturing of multilayer printed circuit boards, the cost involved is higher than that of single and double-layered boards.

- On account of the sophisticated functionality, there is the need to conduct extensive tests when it comes to multilayered boards.

- The complexity of boards can also have an impact on the manufacturing cycle.

- Repair of a multilayer PCB can prove to be difficult. In case of failure therefore, there may be the need to replace the board.

Needless to mention, however, that these issues are not withstanding, the usage of multilayered PCB is only slated to grow.

Uses of Multilayer PCB

On account of the significant advantages that multilayered PCBs offer they find extensive application in a range of appliances including but not limited to:

- GPS and satellite systems

- Computers and ancillaries

- Medical Devices

- Military use

- Consumer products

- Home monitoring equipment

- Industrial controls, and more.

Processes for Manufacturing Multilayer PCBs

Multilayer PCBs manufacturing involves the following processes with utmost quality assurance:

- Combining alternating layers of prepreg and core materials into a single unit.

- Heat and high pressure is used to ensure uniform encapsulation of conductors.

- Careful drilling of holes among the various layers. It is important to ensure symmetrical layout across layers. This ensures that there isn’t a chance of twisting when heat and pressure is applied.

- In identifying the right fabricator, it is important to understand their capabilities. It is imperative that Design for Manufacturing Techniques (DFM) be followed by the fabricator so that there aren’t any costly errors at a later date.

It is imperative to go with a fabricator who has the necessary expertise and experience who can balance the layers in the board stack-up as also analyze how the configuration of the multilayered board will impact the signal integrity of the PCB design.

Mer-Mar Electronics is an ISO 9001:2015 certified company and ITAR (International Traffic in Arms Regulations) compliant manufacturer that delivers multilayer PCB assembly with specialized support, reliable testing, and multi-functional features. Our consistent quality and quick turnaround endear itself to our customers, who look on us as a one-stop-shop for all their PCB requirements. In case you have any questions or require more information about multilayer PCB assembly and fabrication services, get in touch with us via sales@mermarinc.com or call us on (760) 244-6149.