How to Repair Your Medical Printed Circuit Boards without schematic diagram?

Rapid developments have been happening in the Science and Technology field and many advanced pieces of equipment have seen the light of the day especially in the health and medical sector. There has been a constant surge in the evolution of advanced and sophisticated medical equipment and devices. The endless opportunities in medical equipment have increased the functions, introduced a degree of automation, and constant improvements have been happening. The electronic schema is often intricate and complex.

YOU MAY ALSO LIKE: Identify PCB Repair Service Provider

Medical devices need a high degree of precision and even a small anomaly can break down the device that can have life-threatening consequences. So you need to do constant monitoring and also repair them for keeping the functionality intact. If you are relying on imported medical equipment, quite often you won’t be having medical electronic circuit board schematic drawings with you. Without schematic diagrams, one finds it difficult to troubleshoot the controller card. You need to go for reverse engineering if you have to find out a few details about it.

In fact, one of the traditional things in the process of medical equipment PCB maintenance is repairing PCB without schematic design. But as mentioned, it is often difficult to inspect and troubleshoot electronic instruments without the printed circuit board schematic diagrams. If you send it to the PCB contract manufacturer, they would replace the entire circuit board.

To start with the troubleshooting process, you can look into the peripheral failure points. You can notice the failure phenomena carefully for finding an effective solution for the repair process.

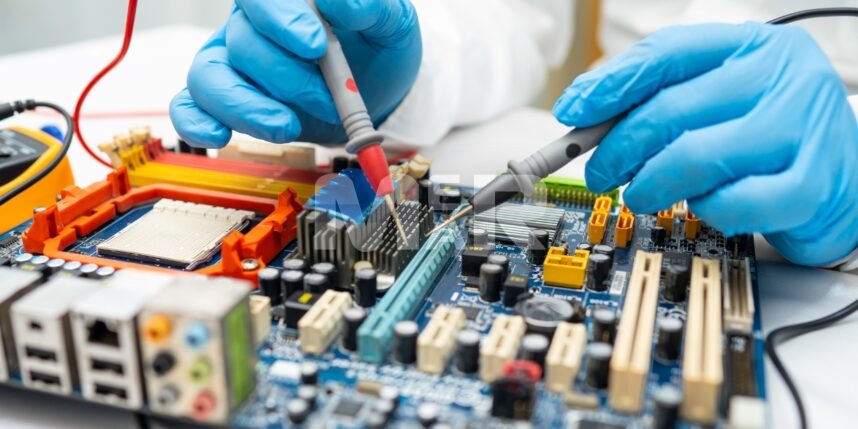

First of all, monitor the PCBs using microscopy and check if there are any break-offs on your medical printed circuit board. Suppose you’ve found any break-offs, look if they can be found on the resistors, transistors, electros, diodes, and triodes. Also, see if the PCB was restored and repaired earlier. If it was, then what are the components that were touched earlier? Was there any misconduct like false soldering, cold soldering, or reverse insertion?

Once you confirm that there were no such instances earlier, then you need to go for a multi-meter for testing the resistance value in the ground and in the power supply. Ideally, it should be around 70 or 80 ohms and above. But if it’s too small, you should know that some of the components could have been broken down. Find out what those breakdown components are. For this, you can look at the temperatures of each of the components. The ones with extremely high temperatures are the usual suspects.

Once you do the preliminary inquiry, let us look into how you can repair your medical PCB in the absence of schematic designs. Focus on 4 essentials for the rehabilitation of the medical electronic equipment.

- Monitor – The first thing you can start with is to see if your medical equipment’s motherboard that needs to be repaired has any visual damage. Can you spot anything from the appearance? Is the environment and maintenance of the medical equipment clean and neat? Are there any visual anomalies?

- Smell – Odor is another thing you can rely on to find out if there are any issues. For instance, if there is any burning that’s happening, you can sense it through odor and find the area where it is happening.

- Question – You can ask the service operator about the device, its life, and the threats that result in the operator’s failure. By asking the questions, you can find out if there are any errors in the operations.

- Check whether the adjustable knobs on the instrument panel are in the right position and normal.

- Also, check the power supply insurance, power terminal board, stabilized power supply, external connection host cables, and other plugs. See if everything is in its normal place, correct and intact.

If there are any differences or disturbances in the above, the entire instrument would be a failure. Remember without schematic designs, even a veteran engineer finds it hard to fix the issues in the printed circuit board.

Conclusion

There is a bundle of things you need to perform for repairing your medical PCBs that do not have the schematic designs. Most important is the experience. Some have mastered the ability to repair the medical PCBs by putting in the requisite efforts and time for exploring the Medical electronics repairs be it simple or complex ones.

As Leading PCB manufacturing company in California Mermar Electronics offer full range of PCB assembly and manufacturing service of all sizes with high-quality PCB prototype to production. We are capable to assemble everything from Head to Toe Medical diagnosis and Treatment devices, Healthcare monitoring devices, Advanced therapeutic treatment devices and other critical medical electronics. We understand the critical nature of medical industry and provide the end to end solution to the clients from the medical industry.