How Automation in PCB Fabrication is Meeting the Needs of Today’s Industries?

Think of PCBs and you tend to increasingly think of complex, high-density, multi-layered boards. With industries such as computing, telecommunication and IoT especially, you are particularly talking about highly complex and miniaturized products necessitating such boards. We are already increasingly seeing trace and space widths of 1 mil being considered.

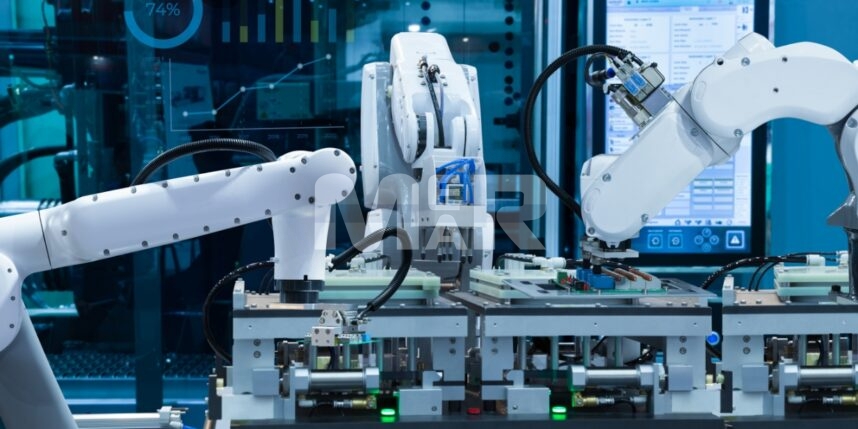

While in its early stages, PCB manufacturing was a manual job, today’s technology and the need for increasingly small boards, calls for the need for a high degree of automation. In fact, it would be near impossible to mass-produce these delicate boards without an automated assembly process. Besides the mass production of boards, automation also brings about a host of other benefits.

Benefits of automation in PCB Fabrication

Automation in PCB fabrication comes with a range of benefits, including but not limited to:

Cost advantage

Shorter assembly times

Low chances of error

Higher Quality

Miniaturization

- Cost advantage – There are no doubts, that as opposed to manual assembly, which involves a sizeable labor cost, the running expenses when it comes to automation are far lower. In turn, this translates into optimal product pricing, which can be huge source of competitive advantage.

- Shorter assembly times – With faster time-to-market being yet another important criterion in today’s hugely competitive world, what automation importantly also offers is a faster assembly time.

- Low chances of error – Manual assembly can also come with high probability of manual errors, which in turn can lead to costly mistakes. Automation in PCB Fabrication, however, takes away the scope of these errors and ensures that you have a quality product and complete peace of mind.

- Higher Quality – Reduced errors automatically translate into high quality PCB fabrication, which in turn determines the quality and reliability of the end product.

- Miniaturization: As mentioned above, given the constantly reducing size of gadgets, the need of the hour is to create miniature PCBs with high component density. Again, this is a task that automation can achieve. Automated systems can go a long way in sorting out parts, placing components correctly and even perform testing. With a manual intervention most of this isn’t possible, given the high component density.

What are some of the automation used in PCB Manufacturing?

Typically, when you think of automation in PCB manufacturing, you tend to think largely of robotics in terms of assembly. However, there is a lot more to automation ranging right from component marking right up to packaging and testing. Some of the automated systems being used by a best-in-class PCB Manufacturing service today, include:

- Automated system of marking and labeling components

- Machines that can pick up small components and place them on the board

- Automated soldering systems

- Routing machines

- Automated systems for inspection

- Test systems such as in-circuit tests or flying probe tests to ascertain manufacturing integrity.

- Conveyors for transporting boards

- Bar code readers for tracking components

- Packaging systems to seal the final products as and when they are ready.

In fact, as PCB technology continues to advance, reliable Contract Manufacturers will continue to look for new and improved automated manufacturing systems to further streamline processes and to add to their efficacy. These will also include newer testing techniques that ensure that any errors do not go undetected.

It is imperative, therefore, that you choose a PCB Manufacturing service that that is committed to maintain a high level of automation that in turn, ensures high quality PCBs at the lowest possible costs. By ensuring this, you are making sure that the PCB fabrication service is not only geared to handle your current requirements, but is also equipped to tackle the changed landscape that is sure to develop in times to come.

At Mermar Electronics, we offer a one-stop solution for contract manufacturing and PCB fabrication. With our goal being to provide consistent product quality with quick turnaround time, we rely on the highest degree of automation. It is on account of this that we are also able to provide the highest degree of customer service and reliability to our clients. You can count on us to meet and exceed your PCB Manufacturing needs. We are ever committed to staying ahead of the curve, when it comes to meeting the growing demand for different types of PCB Fabrication Services.

Get a quick quote for PCB Fabrication!