The requirement of PCB panelization in PCB manufacturing!

There is no doubt about the fact that PCB assembly is an extremely complex task that needs the highest degree of skill and efficiency. One thing that goes a long way in aiding the process is to use panelization.

YOU MAY ALSO LIKE: PCB Manufacturing Requirements

What Is Panelization?

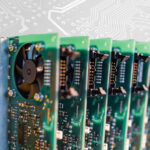

PCB Panelization means grouping together of boards, which in turn aids the processing speed. Panelization is particularly common in the case of high volume as well as quick turn orders when optimization is of particular essence. With smaller boards connected together it becomes far easier for them to go past the assembly line. The boards can later be easily removed.

How Panelization in PCB Works?

The process of panelization typically works as follows. The first step involves the fabricator building blank boards. In the next step, the designer arranges these boards on to a larger board. The number of layers can exceed as many as 42 depending on how intricate the circuit is. It is easier if the boards are of regular shapes as odd shapes can make the layering process difficult. The array is then processed as one consolidated panel. What it means is that machines can fix components to boards easily.

However, it is important to take into account the following:

- Array strength: Typically, an increase in board count in each array adds to the overall strength.

- Layout: It is important to take into account the location of sensitive components towards the edge.

- Shape: It is ideal if you are dealing with rectangular shapes.

- Tooling holes: Arrays can often provide tooling holes’ spaces for automated testing.

Advantages of PCB Panelization

With PCB Panelization, production efficiency is significantly improved. Some of the advantages of panelization include:

- Mass production – It is especially helpful in mass production where it optimizes time & money

- Safety– Assembly often involves a lot of vibration. This is something that panelization protects the PCB from.

- Speed – With multiple boards being processed at once, speed is a given. Whether it refers to soldering or testing the process becomes much faster

Some of the restrictions on panelization, however, include the fact that it isn’t too useful for low-volume PCB fabrication. Also, panelization is limited by factors such as:

- Board thickness

- Component weight

- Space between boards

To ensure panel efficiency:

- Boards should be of similar size

- By and large the parameters of the board must be similar

- There should be a similar copper distribution

PCB Panelization Methods

There are different ways in which panelization can be done:

1. V-groove Panelization

This involves making a V shaped line between boards and is useful when there are no overhanging parts

2. Breakaway Tab

This is a method of perforation between the individual boards.

V-Groove Vs Tab Routing – Best Panelization Method

Choosing whether you should use V-score or a tab routing method depends largely on the design.

- Shapes: Typically, V scoring works well for regular shapes while tab routing works for unusual shapes.

- Edge Components: For components placed close to an edge, tab routing may work better than v-scoring.

- Edge Quality: Again, in terms of edge quality, tab routing is preferable

- Time: V-scoring works better from the point of view of the time required.

- Waste: In terms of material waste, V scoring is preferable as it reduces waste material and thereby leads to lower overall costs per board

PCB Panelization Guidelines

Here are some broad guidelines to be followed for panelization:

- For routed rectangular panels with sides greater than 1.00”, 100 mil needs to be added between PCBs along with a 400-mil border on the outside. However, in case the length is less, 300 mil needs to be added between PCBs

- For non-rectangular PCBs, 300 mil space needs to be added.

- In the case of V-scoring, a 0-mil space needs to be kept between the PCB board edge and the traces with 300 mil on the opposite sides.

However, there are some exceptions to the thumb rules above:

- To ensure that de-panelization does not result in damaging the component, the border between the PCBs needs to include the overhang distance.

- To add to the mechanical strength of the panel in case of a heavy component, additional material needs to be added between the boards.

Another thumb rule to be followed is that the clearance between the metal and PCB board needs to be 5 mil in case of routing. In case of V-scoring, however, it needs to be as much as 20 mil.

Also, in the case of using breakout tabs, it is the size and shape of the board that needs to determine how many breaks out tabs should be used.

PCB Depaneling

Once the assembly and testing are done, the next step is the reverse of panelization or depanelization. Depending on the panelization method chosen, depanelization or separating into different parts can be done in many ways. Some of these include:

PCB Panel Separation Methods

- Breaking by hand

- Cutting along the V Grooves

- Saw cut

- Laser Cut

- Punching out of boards etc

To sum up, it is imperative that the boards be designed with panelization in mind. This will ensure that you have to deal with minimal delays as well as take away the need for too many redesigns.

Get a Free Quote for PCB manufacturing!