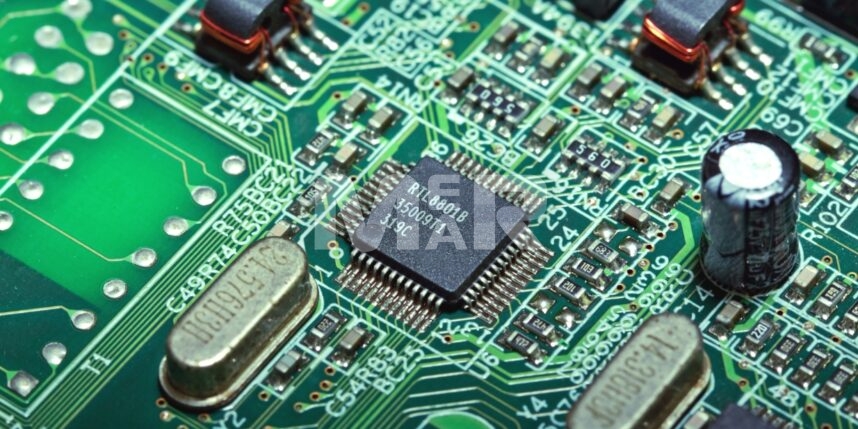

The role of IOT in PCB Manufacturing business

With electronic devices becoming ubiquitous in today’s world, what has also become ubiquitous in its presence is the emergence of a new phenomenon called “Internet of things”. It is not without reason that that IOT has been called the fourth Industrial Revolution.

In fact, the core of all electronic devices, IoT, is today revolutionizing PCB-driven devices. Here are only few examples of this revolution:

- Smart home devices– A whole lot of smart home devices today are driven by PCBs. Whether they are computer systems or wall mounted tablets, IoT has a significant role in all these PCB based applications.

- Automotive: Whether it is the use of an electric car or a bullet train, the importance of IoT in the automotive sector cannot be over emphasized.

- Fitness trackers: Many wearable apps that use advanced versions of PCB such as Flex PCBs and HDI PCBs are powered by IoT technologies.

In each case, PCBs are at the crux of these devices enabling the use of IoT. It is the use of PCB that enables revolutionary ideas to come to life such as navigating real time traffic through the use of GPS devices.

With the use of Flex & HDI PCBs, it is possible to overcome the design limitations that make the PCBs suitable for IoT. Some of the advantages of such PCBs include:

Reduced size:

Unlike rigid PCBs, flex PCBs allow both a reduced size as well as dense circuitry.

Light weight:

Reduced size also comes with the advantage of light weight which in turn makes the device far more portable and versatile.

Improved Durability:

Flex PCB Materials also add to the device’s durability and its ability to stand up to harsh conditions.

Improved wiring:

With simplified wiring that eliminates mechanical connectors, it becomes an asset for IoT functions.

Cost effectiveness

With reduced need for layering, smaller sizes and more these PCBs also come at cost effective price points.

IoT PCB Design Tips

In designing a PCB that is ideal for IOT use, a number of key design areas need to, however, be kept in mind. Here are some areas to watch out for:

- Size- With devices becoming progressively smaller, PCB designers do not have the luxury of space. HDI & Flex boards therefore have a very important role to play. IoT product designers also need to play a very important role in the designing phase itself.

- Non-traditional materials- Ever so often non-traditional materials such as mesh or plastic may have to be employed for improved functionality as also to ensure that the design elements are incorporated. Clearly then, the days when square shaped PCBs were the industry standard are long over.

- Adapting for the human body- In case the IoT product is one that is a wearable, it is imperative to ensure that the mechanics are such that they aren’t affected by the human body temperature. Similarly, there are issues of radiation and humidity. Moisture, for example, can totally impact the circuit and needs to be planned for. A package that is fully sealed and moisture resistant can well be the answer. You could also apply a conformal coating that doesn’t allow moisture to percolate.

- Consumption of power- With IoT comes the need of an improved battery life. Power consumption thus needs to be planned carefully and testing needs to be done meticulously. In fact, each circuit block on the PCB needs to be allotted its power budget so that over all power budgets can be minutely planned. Having different validations for standby, Rx etc can go a long way in impacting usage of battery.

- Reliability- Designs also need to be tested for reliability as there is increased pressure on the fact that devices need to stand the test of time when it comes to durability.

- Wireless connectivity – The right wireless modules and RF circuit components need to be used. Also in choosing these parts, the power consumption as well as network range and speed needs to be factored in. Basis a number of different factors, one or several of the protocols mentioned below, will need to be employed.

In case of infrastructure, protocols such as RPL or 6LowPAN may need to be employed. For Identification, EPC or URIs may need to be put in use. Communication and transport will have to rely on Bluetooth or WiFi. Similarly for Data, Websocket or Node may need to be used.

All the above factors necessitate the fact that there is proper communication during the design stage as also the need for meticulous testing.

Going forward while the demand of IoT will only increase, what needs to be seen is that whether some amount of standardization can be brought into the process. While needs many be individualistic, it is a possibility that some design protocols can be standardized. The interface of PCB & IoT is really in the initial stages and a lot of their interaction remains to be seen. What is a given, however, is that demand is only likely to rise.

Get a Free Quote for PCB manufacturing!