Leading the way for over 40 years

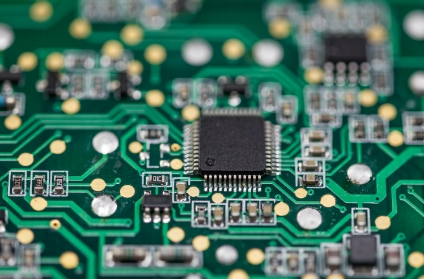

When it comes to Military Grade PCB, you cannot rely on just about any PCB manufacturer. After all, these are boards that need to operate flawlessly under harsh conditions. What is needed therefore is that they be manufactured with high precision and minimum tolerance.

To meet Military or IPC Class 3 specifications, a PCB must be designed from scratch as a Military Spec or IPC Class 3 part. At Mer-Mar Electronics, we have the necessary experience and expertise to undertake the design, layout, material selection as well as fabrication process to meet the stringent standards. Our Military PCBs are manufactured in conformance with MIL-PRF-50884, MIL-PRF-31032, and MIL-PRF-55110 standards. In designing of these PCBs, below are some of the aspects we keep in mind:

- The components selected are of Mil-spec grade which have tight tolerances

- The PCBs are designed to handle maximum current load

- Heat resistant materials such as Pyralux AP, FR408, and other metallic core components are used

- High clearance space is accorded to high heat producing components

- Pre layout simulations and impedance is made to see how the PCB works in real time

- The finishing materials used are such that they support PCB performance in harsh environmental conditions

- High quality software simulation programs are used to check the PCB design so that there are no costly errors at a later stage.

Why is Mer-Mar Electronics your go-to place

for Military Grade PCB Requirements?

State-of-the-art facility – At Mer-Mar Electronics, we have the necessary technology to ensure we deliver Military Grade PCBs that adhere to stringent industry norms. Our team of experts are equipped with the industry best practices right from design to fabrication to ensure a flawless product.

Stringent manufacturing Processes – Strict adherence to industry standards and best practices ensure that the PCBs conform to Military or IPC Class 3 specifications and work flawlessly in the most unsuitable environmental conditions. In addition our robust testing protocols do not leave room for errors.

Quick turnaround time – With time being of essence when it comes to mission critical PCBs, we offer quick turnaround times irrespective of the quantity that you require. Rest assured that quality is never sacrificed at the altar of speed.

Military Grade PCB Services

Military spec design services

Mil Spec PCB design requires a different level of expertise and experience as opposed to commercial PCBs. Some of the many aspects that need to be taken care of include isolation of low frequency components from high frequency ones, shielding of clock signals, running pre-layout simulations and more. At Mer-Mar Electronics, we have experienced designers who are well-versed with the best practices for class 3 PCB design.

Component selection and integrity

Count on us to help you with component procurement that follows component authenticity protocols and ensures component integrity. Additionally, our Component Engineering Team helps support and mitigate any obsolete, end-of-life components.

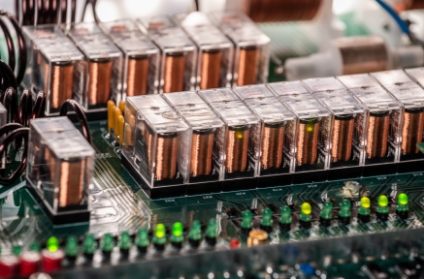

Military PCB Fabrication and Assembly

With our superior technical expertise we ensure that your board’s manufacturing and PCB assembly meets the stringent standards set for military PCBs. You can count on us for turnkey Military grade PCB services to ensure everything is taken care of end-to-end without any hassle.

Testing regimen

As a contract manufacturer with critical systems expertise we follow stringent testing protocols beginning right from pre layout simulation to ensure the highest quality for your boards. We also offer environmental testing including:

- Shock & Vibe Testing

- Thermal Cycling

- Burn-In

Military PCB Packaging

Military Grade PCBs need specialized packaging with moisture barrier grade material. In addition, it requires high quality performance bonding, sealing, coating, potting, encapsulation materials. Our packaging services ensure that products do not crack, peel, shrink, corrode, change color or lose mechanical strength.

As opposed to regular commercial PCBs there are certain aspects that need special focus when it comes to manufacturing Military grade PCBs. These include:

PCB design and layout

Military grade PCBs need to follow some stringent PCB design and layout considerations. From according high clearance space to shielding of clock signals by creating a material enclosure, there is a lot that needs specific attention.

Design for Test

Another important aspect when it comes to Military grade PCBs is that they are designed for test. Essentially this means that there is a clear focus on easy access to components so tat they can be tested in isolation from the rest of the equipment.

Choosing the right components

It is imperative to go with reliable components with fine tolerances. It isn’t enough to go with a generic description of parts but to stick to specific manufacturer and part numbers in order to maintain component integrity. Similarly, choosing the right laminate and prepreg material for the substrate is important. Some of the factors that go in to make the choice include:

- Glass Transition Temperature

- Decomposition temperature

- Coefficient of thermal expansion

- Thermal conductivity

Choosing the right methods

Some of the other aspects that need due attention as opposed to commercial boards include:

- Minimum conductor spacing acceptability

- Through hole plating wall thickness

- Drill hole breakout acceptability

- Board thickness to via size ratio

- Aspect ratios that must not exceed a ratio of 10:1. If this ratio is overstepped the board’s physical strength is compromised. Also the boards are costlier to fabricate

- Separation of frequencies is an important aspect as high frequency units can cause signal cross interference and distortion in low frequency components and vice versa.

- Clean clock signals are another area of importance in military grade PCBs as they are deployed in equipment that are designed to run for a long period of time. There also needs to be no interference in case more than one clock signal is running.

- Digital and analogue circuits need to be kept separate

- Trace routing needs to be done in a manner so there is no echo. To do this corners of more than 45 degree are avoided and it is ensured that the trace follows a curved route. With sharp corners there is always the issue of water and electrical circuit not flowing smoothly.

- There also needs to be proper thermal management in high voltage systems that are expected to run for a long time. This involves using heat sinks to dissipate heat. Metal base PCBs also help in thermal control.

- In addition, it is recommended that military grade boards stick

to the following specifications for best results:

- The dielectric thickness between two planes: 3.5 mil minimum

- Annular ring for inner layer: 6 to 7 mil

- Annular ring for outer layer: 6 to 7 mil

- Drill to copper clearance: 7 to 8 mil

With this kind of attention to detail, seamless PCB fabrication as well as compliance is ensured.

– 02

Mil Spec PCB Capabilities

At Mer-Mar Electronics, the following are our capabilities when it comes to Military Grade PCBs:

- 1- 20 layers

- Types of PCB- Standard rigid PCBs, flex and rigid flex PCBs

- FR4/ Polyimide Material

- 0.5-0.6 Oz

- Hole Aspect Ratio: 12:1

- Minimum Hole Size: 0.006ʺ

- Minimum Trace/Space 0.004ʺ/0.004ʺ

- Final Finish: HASL (Solder), Lead Free Solder, copper, gold, gold fingers, OSP, white tin

– 03

Application of Military Grade PCBs

Military Grade PCBs find extensive application in the following:

- Cyber counterintelligence systems

- Cryptanalysis systems

- Automation networks

- Automatic search jamming systems

- Radio communication systems

- Radar installations

- Power converters

- Power supplies

- LED lighting systems

- Instrumentation

- Control tower systems

- Temperature sensors

- Audio interface applications

Military Grade PCB FAQs

Are you looking for Military grade PCB assembly, Mil Spec PCB assemblies, defense or custom printed circuit board assembly? Send us inquiry to Get a Quick Quote based on your custom requirements.

If you have any queries regarding to our Military grade printed circuit board service or need an urgent assistance, then please don’t hesitate to contact our team of skilled personnel’s. Send us an email with your queries at sales@mermarinc.com or call us at (760) 244-6149. We are looking forward to hearing from you.