Leading the way for over 40 years

We are a flex PCB manufacturer who have been manufacturing flexible PCBs for over 40 years and pride ourselves on producing the highest quality PCBs. We have a state-of-the-art infrastructure and a team of experienced professionals who are passionate about every project we undertake. Our industry-leading practices ensure that you won’t have to make costly mistakes. We’re here to help you achieve your goals with the best possible results.

What is Flex PCB?

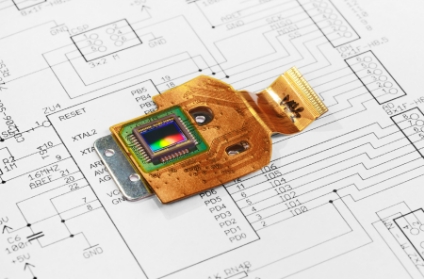

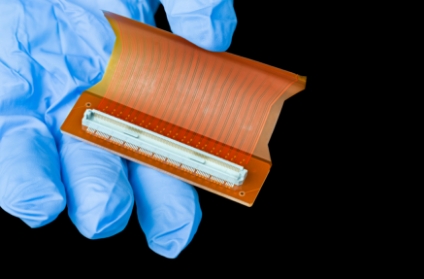

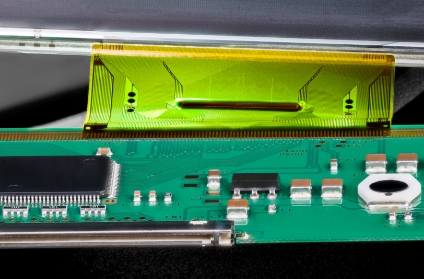

Flexible PCBs (Flexible Printed Circuit Boards) are electronic circuits that are manufactured on a flexible substrate material, typically made of polyimide or polyester. These flexible substrates allow the PCBs to be bent, twisted, or folded into different shapes to fit into tight spaces or to conform to irregular surfaces.

Flexible PCBs are commonly used in applications where space is at a premium, such as in medical devices, aerospace, and consumer electronics. They offer numerous advantages over rigid PCBs, including reduced weight, increased reliability, and improved signal integrity. Flexible PCBs can also reduce the number of interconnects required, which can result in lower assembly costs and improved performance.

Meet Your Unique Requirements With

Our Flexible PCB Services

State-Of-The-Art Facility

Our superior equipment and experienced manpower translate into high quality PCBs. No matter how complex the design with blind/buried vias or how many layers you require, we have the necessary expertise to offer you quality products.

Stringent Manufacturing Processes

Strict adherence to IPC guidelines and industry best practices ensures a high degree of reliability. In addition, our robust testing protocols do not leave room for errors.

Catering to All Volume Requirements

From prototype quantities to full production runs, we cater to all volume requirements. What this means is that you do not have to worry about scaling up operations at any point in time.

Quick Turnaround Time

Quick go-to-market is the source of one of the largest competitive advantages in a crowded market. Our quick turnaround times ensure that you reap this advantage.

Flexible Printed Circuit Board Services

Flexible PCB Fabrication

As a manufacturer and supplier of flexible PCBs, we are well equipped to provide wholesale flexible PCB fabrication with high layer and ultra-dense component counts, conformal coating & potting, complete mechanical assembly, fixtures and fixtureless in circuit or functional testing,turnkey, consignment or mixed model or any other requirements of clients. Our reliable flexible printed circuit boards are being selected by multiple industries!

Heavy Copper Flexible PCBs

If you are looking for boards with high thermal management capabilities, you can count on us to provide you with heavy copper flex boards. They offer several advantages such as easy integration with high-power circuits and control circuits as also increased current carrying capacity. Our expertise is in manufacturing heavy copper flexible PCBs in a cost-effective way and with proven design. Our team will review your design and ensure it is manufactured with the highest quality and standards.

Flexible PCB Design

From material to vias, our experts take several factors into account in flexible PCB design. Some of the aspects that go into our flex circuit board design include the operating environment, bend ratio, vias, controlled impedance, signal integrity and more. Our range of flexible printed circuit boards are designed with a wide range of configurations and custom specifications.

Flexible PCB Finishes

Count on us to offer you a wide variety of circuit board finishes such as ENIG Gold; OSP, Immersion silver, Immersion Tin, HASL, and more. We ensure that the finish options are suggested in a manner that complements the functionality and environment of the application and improves product performance. Our range of flexible PCBs is fabricated in response to the requirements of several industries and market trends.

Flexible PCB Repair & Rework

If you encounter problems such as ripped or cut flexible PCB material, heat-damaged pads, or damaged conductors, we can provide you with meticulous flex PCB repair and rework services. Our team has hands-on experience in repairing and reworking flexible printed circuit boards with a high degree of precision.

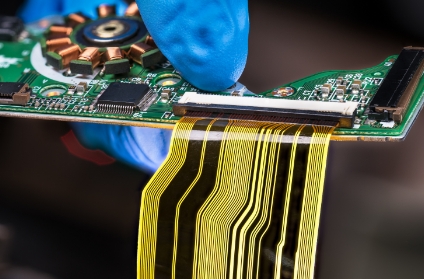

Flex PCB Assembly

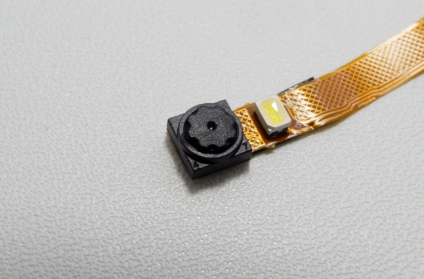

Flex PCB assembly refers to the process of attaching electronic components to flexible printed circuit boards. Flex PCBs are ideal for applications where space is limited or where a board needs to be bent or twisted. The assembly process involves placing and soldering components onto the flexible board, followed by testing to ensure that the circuit functions correctly. Our service provides expert flex PCB assembly for a wide range of applications.

– 01

Flexible PCB Manufacturing Process

The detailed process of fabricating Flexible PCBs involves the following steps:

1. Shearing

This step involves cutting the material as per different sizes, designs and layout specifications.

2. Drilling

Depending on the exact design, this involves drilling different holes such as alignment holes, testing vias, component holes and more.

3. Through-Hole Plating

Post drilling the next step involves through-hole copper plating to establish connection between layers.

4. Dry Film Lamination

Pre-treated boards are passed through hot roller to laminate the dry film on it.

5. Exposure

The designated circuit pattern image is transferred to the dry film to create an exposure area.

6. Development

By casting UV light on the film, the dry film on the exposure area is hardened while the one on the non-exposure area can be removed.

7. Etching

This process involves initiating a chemical reaction on the non-exposure area and ensuring the protected area remains unchanged.

8. Stripping

At this stage, the dry film covering the circuit pattern is removed.

9. AOI (Automated Optical Inspection)

A robust process, this checks the quality of the circuit boards.

10. Coverlay Pre-lamination

An insulating layer called the coverlay is introduced to protect the circuit boards.

11. Hot Press

Next, the board is passed through a hot press to ensure adhesion.

12. Metal Coating

The bonding area is coated with metal, often gold or nickel.

13. Screen Printing

Silk screening is applied to print information such as logos.

14. Testing

Robust electrical and functional testing ensures efficacy of the circuit boards.

– 02

Advantages of Flexible Circuits

1. Reduced Assembly Time and Costs

Not only do they require less manual labor, but they also take away the high cost of routing, wrapping and soldering wires. The fact that they also lend themselves to reduced errors in flexible printed circuit assembly, is an added perk.

2. Freedom of Design

As opposed to rigid boards that offer restrictions, flex boards offer endless design options. In fact, at Mermar Electronics, as a flex PCB manufacturer, we take great pride in designing highly complex flex boards that can stand the test of time in harsh environments.

3. Ease of Installation

Once again, as opposed to rigid boards, flex PCBs lend themselves to ease of installation. With flex boards you do not have to contend with space or weight issues.

4. Ideal for high-density Applications

With miniaturization being the need of the hour, the demand for flex PCBs has increased as it frees a lot of space and can fit in easily.

5. Improved heat dissipation

With the compact design of PCBs, it allows a shorter thermal path and hence lends itself to improved heat dissipation.

6. Maximum Reliability

With fewer interconnections, Flex PCBs offer improved reliability.

7. Reduced Weight

Flex PCBs are extremely thin; they allow not only for streamlined designs but also reduced package size and weight.

– 03

Flexible Circuits Capabilities

At Mer-Mar Electronics, the following are our capabilities when it comes to Flexible Circuit Boards:

| Layers | Multilayers up to 20 layers |

|---|---|

| Minimum Annular Ring | 4 Mil |

| Copper Weight | 0.5-2.0 Oz |

| Minimum Hole Diameter | 8 Mil |

| Materials | PI, PET, PEN, FR-4, Polyimide (Kapton), Adhesiveless Copper Clad Base Material, High Performance Epoxy Laminate and Prepreg, and High-Performance Polyimide Laminate and Prepreg. |

| Stencils | Laser cut stainless steel and Nano-coating |

| Surface Treatments | Lead-free: ENG Gold; OSP, Immersion silver, Immersion Tin |

| Max / Min Board Size | 0.2″ x 0.3″ Max: 20.5″x13″ |

| Copper Thickness | 1/3oz – 2oz |

| Max / Min Insulation Thickness | 2mil/0.5mil (50um/12.7um) |

– 04

Application of Flexible PCB Fabrication

Flexible circuit boards find both static as well as dynamic application. While a static application involves designing circuits with a small amount of flex, a dynamic application involves the circuit being flexed repeatedly. Such applications are designed with RA Copper.

Some of the industries that Flexible Circuit Boards find extensive application in include:

- Electronics

- Manufacturing

- Automotive

- Medical

- Aerospace

- Military and Defense

- Telecommunications

- Transportation

Flexible PCBs FAQs

Looking for flexible PCBs, flexible PCBs fabrication or any custom flex printed circuit boards for your Next project? Send us inquiry to Get a Quick Quote based on your custom requirements.

If you have any queries regarding to our flexible PCBs or need an urgent assistance, then please don’t hesitate to contact our team of skilled personnel’s. Send us an email with your queries at sales@mermarinc.com or call us at (760) 244-6149. We are looking forward to hearing from you.